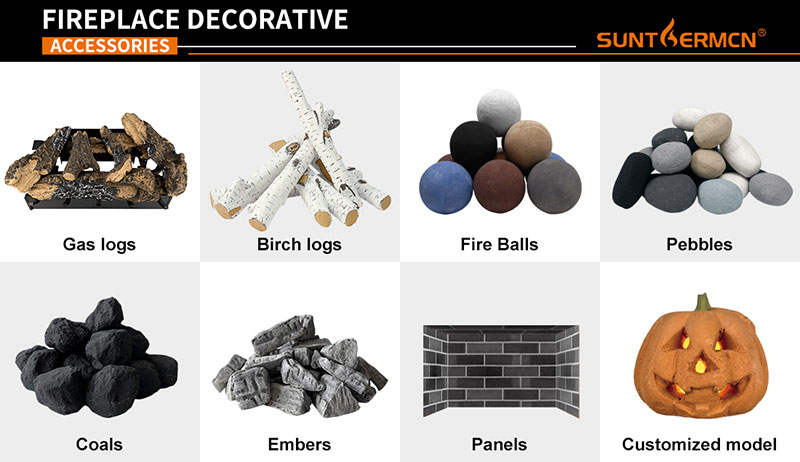

products

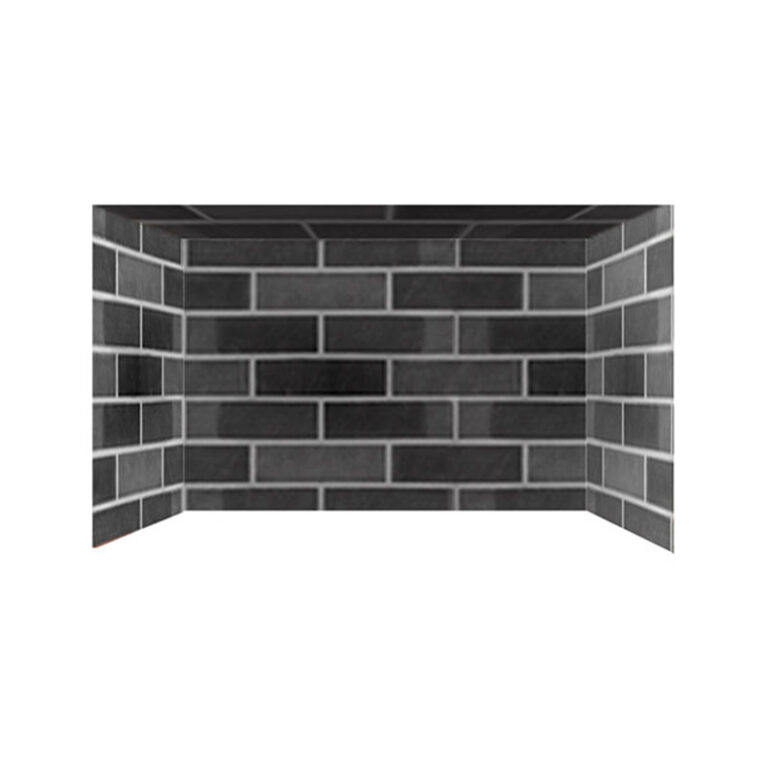

Ceramic fiber brick panels Fireplace back chamber boards Gas fireplace logs Back Board

Ceramic fiber brick panels have high thermal performance, their role is to withstand the high temperature of the fire, protect the surrounding metal fire box. Without this protection, heat can be transferred to the metal housing, causing it to warp, weaken or worse. Sunthermcn fireplace panels increase the overall strength and stiffness of the fireplace.

Installing ceramic fiber brick panels is an easy and cost-effective way to cover exposed fireplace spaces and give your fireplace a beautiful, uniform, consistent look.

| Brand Name | SUNTHERMCN |

|---|---|

| Item Number | SUN-LMZ001 |

| Material | Ceramic fiber |

| Product name | Ceramic fiber brick panels |

| Certificate | CE/ISO/SGS/BV Certification |

| Suit for | Electric/gas fireplace, fire pit |

| Feature | Eco-Friendly |

| Appearance | Natural and realistic |

Products Description

Ceramic Fiber brick panels Fireplace back chamber boards Gas fireplace logs Back Board Fireplace Plate

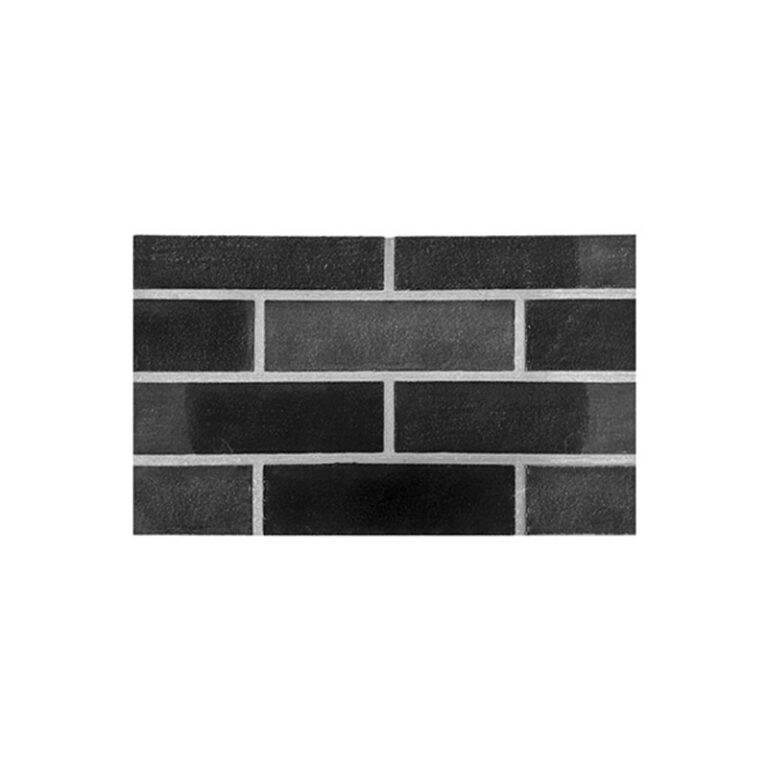

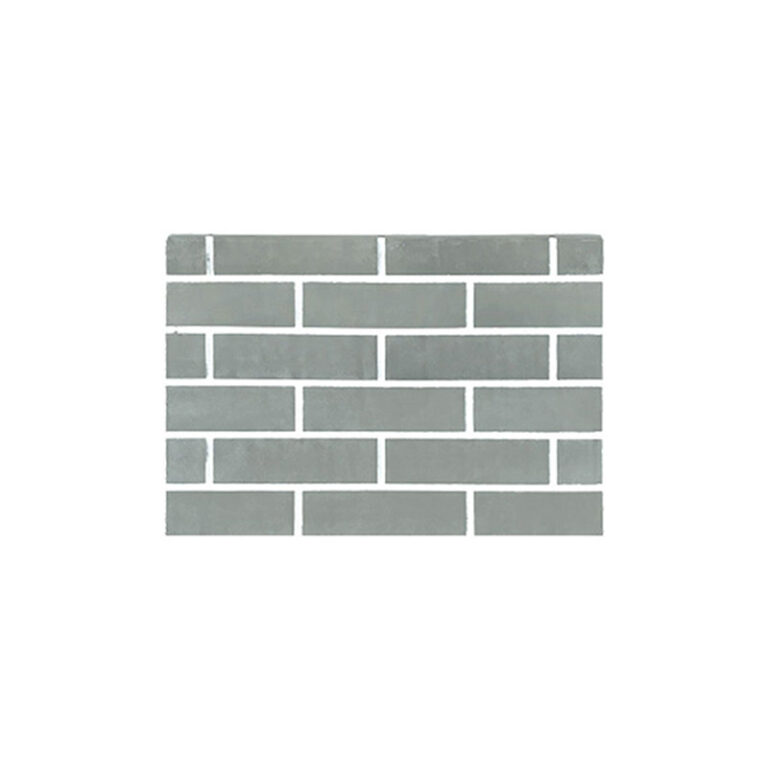

Ceramic fiber brick panels come in a variety of colors: black/red/yellow/brown/beige/gray, SUNTHERMCN supports customization. With high quality ceramic fiber as raw material, the temperature can be up to 1100 ℃, light weight, easy to install, fade resistance, not easy to break, so that your fireplace has a perfect appearance, which is the perfect decoration of the fireplace.

Product parameters:

Features:

- Material: High quality ceramic fiber

- Temperature resistance up to 1100 ℃

- Light weight, easy to place

- Clean burning, smokeless and odorless

- Resistance to fade

- Highly realistic appearance

- Color, size and style can be customized according to customer’s requirements

Applications:

- Vented gas fireplaces

- Outdoor gas fireplaces

- Indoor gas fireplaces

- Fake fireplaces

- Electric fireplace inserts

- Propane fireplaces

- Direct vent/zero clearance/natural gas/gel/standard fire pits and fire tables

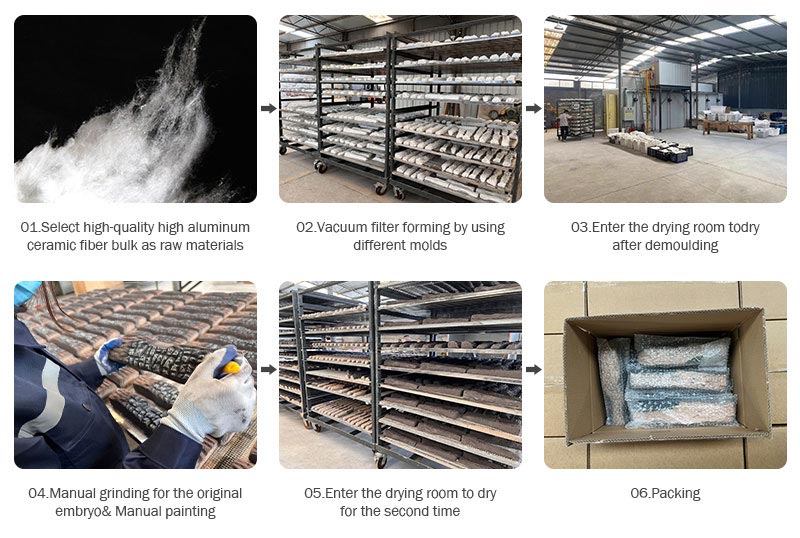

Production Process:

Our Advantages:

Professional Manufacturer:

Over 30 years of experience in the main raw material—ceramic fiber industry

Self-supply of raw materials

17 years’ experience of export

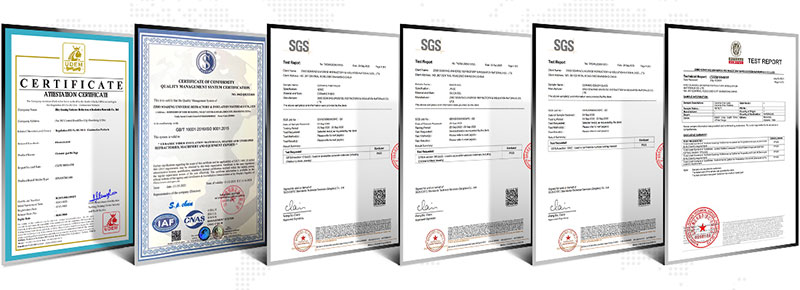

Authoritative Certificate:

ISO,CE, lead content test report—CPSC standard of the United States, and BV combustion test report

High Productivity:

9 ceramic gas log production lines, and the daily output can reach:

Ceramic gas logs: 800 sets/day or 2000-3000kgs/day

Coals/pebbles/balls: 300 sets/day or 500kgs/day

Quality control:

Every link is strictly controlled from raw materials to finished product packaging

Professional quality inspection department to ensure excellent production quality

Innovative Spirit:

Regularly launch new styles of gas logs

Customize exclusive products according to customers’ ideas

Packaging and shipping:

SUNTHERMCN can customize packaging according to customers’ requirements to ensure the safety of goods in transit.

Certification:

FAQ

Q1: What is your manufacturing method?

A1: Vacuum filter forming.

Q2: Can you help me with my own design?

A2: We have a professional R&D team to design new products. You can tell me your ideas or provide us with drawings and we will be happy to design them for you.

Q3: What is your lead time to manufacture?

A3: If it is new style, it needs to be customized, mold making takes 7-10 days.

The delivery time for large order is generally 20-25 days.

Q4: What is your export container load?

A4: The containers we usually ship are 20GP and 40HQ containers. The amount of cargo that each container can carry needs to be calculated based on the size of the actual cargo.